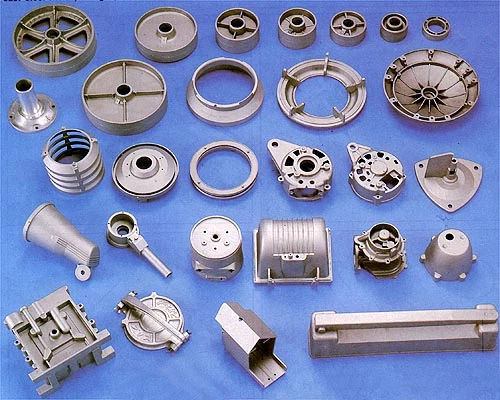

產品內容

The Expandable Cavity was developed for molding undercuts such as threads,dimples,and protrusions on the outside of the piece part.

The patented X-Cav design eliminates the endineering,maintenance,and machining required for side action mechanisms which allows for smaller molds or higher mold cavitation.

"A"Series:

• Forms all of the molded detail

• Requires striker insert in "A"Side of mold

• Gating position must be from top

"B"Series:

• Forms details such as bosses and posts with barbs

• Allows all motion to be in the "B"Side of mold

• Gating position allows for a conventional runner

Contact Engineering for a full design review and quote.

Expandable Cavities mold undercuts such as threads,

dimples, and protrusions.

The patented Ex-Cav design eliminates the engineering,

maintenance, and machining required for side action

mechanisms which results in smaller molds or highermold cavitation.

Technical Information:

• Four sizes offered to satisfy a wide range of parts.

• • The Ex-Cav expands along a conical shape, 10˚ per side.

• • Manufactured from A-2, 54-57 HRC material for repeatable expansion.

For optimal performance, the Ex-Cavs should ride against a hardened

insert.

• • Maximum temperature: 260˚C / 500˚ F

• • Expandable Cavities are capable of operating without lubrication.

However, treating the Ex-Cav with an additional coating for wear

reduction or corrosion resistance is beneficial.

• • Ex-Cavs can be ordered with molding detail for a ‘mold ready’

component.

• • Fixturing bushings for machining details in house are also available.

• • Custom Ex-Cavs are available. Also, when an entire part is formed

within the cavity, an A-Series Ex-Cav can be provided, shown at left.

公司資訊

- 統一編號96917043

- 聯絡人張喜美

- 更多福爾摩沙模具有限公司資訊

專業CNC車銑複合零件加工,以免除二次加工的精度誤差